How to fit a chimney liner

5 mins

How to fit a chimney liner

What is a chimney liner?

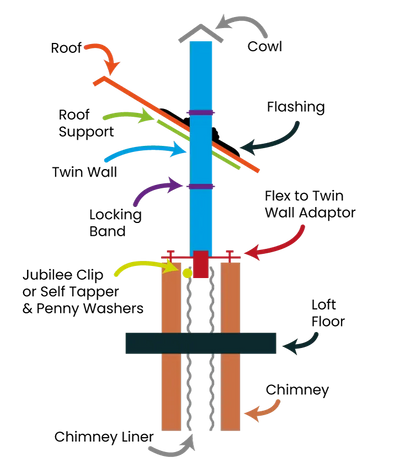

A flexible chimney liner (or “flexi” or “liner”) is a flexible stainless steel tube that is connected to the top of the pipe protruding from your wood burning stove and at the other end within the chimney pot (or attached directly to the cowl).

A chimney liner protects your chimney

It can be seen from this that smoke (and property damaging acids and tar) never come into contact with the inner walls of your chimney (and can therefore also not escape through old/damaged building material and into the property).

There are other methods of lining your chimney other than to fit a chimney liner but to fit a chimney liner is by far the cheapest and most common. A chimney liner is not supposed to be in place of a suitable chimney or used if a chimney has fallen into a poor state of repair (if the chimney has faults they should be repaired professionally before lining).

Building regulations do not insist that you fit a chimney liner. If a chimney can be proven sound (using a set smoke test procedure), AND is of a diameter suitable for the stove, AND the stove-fitter can connect to the chimney in a way that satisfies the regulations, AND the end result is that the stove draws within the parameters laid down by the stove manufacturer, AND it can be swept, AND every building regulation is followed then you do not have to fit a chimney liner – a tough call for even an experienced stove fitter and many will not even consider it.

STOVES WORK BEST WITH A FLUE DIAMETER AS CLOSE AS POSSIBLE TO THAT SPECIFIED BY THE STOVE MANUFACTURER OR BUILDING REGULATIONS.

I have shouted that last sentence to really try to put you off from choosing to not fit a chimney liner. A stove designed to work with a 6″ flue will not perform so well if attached to a chimney with an 11″ diameter! Fit a chimney liner properly, insulate it if required, and there should be no reason for a stove not to perform perfectly: happy dreams for the fitter.

I generally only do not fit a chimney liner if the chimney is new or pot-lined and of a narrow enough diameter.

Possible consequences of not fitting a chimney liner

1. If the chimney is not sound then smoke and Carbon Monoxide can travel into your (or next door’s) property and it can and does kill. I was told the story of a stove fitter who chose not to fit a chimney liner in a terraced property. The fitter smoke tested the chimney but did not seal the chimney for the test (the smoke floated off out the pot). One weekend, whilst the owners were away, Jackdaws built a nest in that pot. Later on the customer lit the stove. Smoke could not escape. Smoke found a hole in the chimney flue and made its way into next door’s chimney. Next door’s chimney was not being used and was blocked at the top to prevent rain ingress. The smoke exited via a vent (designed to air the chimney) in next door’s bedroom. The Carbon Monoxide killed the sleeping neighbours in their beds. Note: that’s why a CO detector in all bedrooms as well as the stove room is a good idea.

2. Hot air (smoke) rises because it is hot – cool it down and it will slow, stop or sink. It does not rise well in cold chimneys, especially where heat-stealing voids, or non-smooth surfaces are present as these steal heat and slow down the combustibles. These combustibles, when slowed, deposit tar and condensation both of which can damage properties (in brick/stone chimneys tar eventually bleeds through the mortar into the house, staining wall papers etc. and is almost impossible to do anything about unless demolition is the tactic). If smoke slows down too much then the smoke behind dams up underneath and the stove burns poorly. Smoke can exit out of stove doors when they are opened to add fuel, and exit the stove via intakes designed to let air into the stove (adding dangerous gases to the room).

3. A chimney fire is more likely (far less likely if lined and would also be contained within the metal tube) if you do not fit a chimney line

Image: Tar staining on cold external chimney.

Liners increase stove performance

Sometimes people say “but I have had an open fire in this chimney for years and no problems”. Open fires are very inefficient compared to stoves and have a very large amount of heat going up the chimney: the heat in most open fires travels fast and out the pot before it has chance to cool and deposit tars etc. With an open fire 70% or more of the heat generated by the fire goes out the top of the chimney. Modern solid fuel stoves are highly efficient with only 30% or less heat going up the chimney (more heat for the room with less out of the chimney). Solid fuel stoves need all the help they can get in keeping that rising air nice and hot (hence liners and sometimes even insulated liners).

What do I need to fit a chimney liner?

A 115mm angle grinder with metal 1 or 2mm cutting wheels (you can use a hacksaw or tin snips).

A length of rope longer than your chimney is tall, twice as long ideally.

A nose cone Included in our fitting packs or available from our store).

Gloves, mask, googles, suitable clothing.

Two people.

Chimney liner fitting - difficulty level

Depends on many factors in particular: the design and height of the property and whether scaffolding is in place/tightness of chimney etc. 5" liner is usually very easy. Avoid 6" unless you know you have a fat flue.

Brains, brawn and bravery all help. Often the whole thing is over in half an hour ;-)

Warning

THE FITTING OF A LINER IS NOTIFIABLE TO BUILDING CONTROL AND YOU MUST NOTIFY THEM PRIOR TO START AND FOLLOW THEIR PROCEDURE. OR EMPLOY A HETAS-FITTER.

There are also safety issues due to “working at height” – I’m not going to get into this can of worms so here’s a elf 'n safety link:

www.hse.gov.uk/pubns/heightsafeleaflet.pdf.

Suffice to say it always looks a lot easier from the ground than it feels when you are up there.

Or get a local roofer to fit your liner and cowl: you can save yourself a few hundred pounds when compared to many specialist companies.

What grade of chimney liner?

For solid fuel (wood/coal) you can purchase liner in two grades: 316 chimney liner and 904 chimney liner. The 904 is the better and has the longer guarantee but is more expensive. 316 usually has a 15 year guarantee and 904 a thirty year - any more than that and the brands are winging it.

Use 904 if you plan on burning coal on anything other than an occasional basis. If burning good quality wood only 316 is fine. If you can afford it go the 904. If your stove has a back boiler go for 904. Or Google it and make your own mind up!

Liner for gas stoves is 316 grade, single-layer and should NEVER be used for solid fuel.

What diameter of chimney liner?

Liner can be purchased in a variety of diameters: 5″, 6″, 7″, 8″, 9″. Rarely will a fitter be fitting anything other than 5" chimney liner or 6" chimney liner.

1. A liner must be 6″ diameter minimum due to building regulations (DEFRA exception see below).

2. A liner must never be of a lesser diameter than the flue size requirement stated by the manufacturer. So if a stove manufacturer states that the stove requires a flue diameter of 7″ then a 7″ liner must be fitted. When buying a stove you will soon see that the flue size requirement (or flue collar size” is stated). NEVER STEP DOWN IN SIZE ANYWHERE ON THE FLUE ROUTE.

3. As stated in (1) above the minimum liner size one can fit is 6″. UNLESS the stove is DEFRA-approved to be used in a smoke control zone. If this is the case AND rule 2 can still be followed then a 5″ liner can be fitted. In other words if the stove is DEFRA APPROVED and the stove manufacturer permits it then a 5″ liner can be fitted.

Many manufacturers will recommend 6″ even though the stove is DEFRA-approved and the flue pipe connector is 5″ and therefore can legally be fitted. They will often do this because there is more room for error if a person does not have their chimney swept as often as they should (a heavily soot coated liner obviously loses internal diameter).

Tip: Unless your chimney is obviously large enough for a 6″ (some chimneys are huge and some you can even see bottom to top) then I suggest you consider the 5″ DEFRA route if possible – especially if the flue is narrow with bends. In these circumstances 5″ liners arer much easier to fit than 6″ liners. i have never had to break open a chimney to assist a 5″ liner round a bend but have done many times with 6″. BUT CHECK FIRST THAT YOUR STOVE MANUFACTURER ALLOWS IT.

Should I insulate my chimney liner?

One can insulate a flexi liner by blanket-wrapping it with a suitable material before inserting it (Chimwrap etc.) or by pouring Vermiculite into the gap between the liner and flue after fitting.

Image below: Massive chimney may benefit from insulation. Vermiculite is out as it would need a hundred bags! So in this case we used a blanket wrap.

If the chimney is exposed (on an outside wall), or the stack is particularly tall, or the flue is of a large diameter then the answer to the proposed question above is - it never does any harm. Insulated liners keep the flue gases warmer, increase the upward speed of those gases and help prevent condensation. BUT I have lined many chimneys, even cavernous ones, without insulation - and they all worked fine.

I speculate that it is not necessary. On a narrower chimney the air between the liner and the flue will insulate the liner.

How to install a chimney liner if not blanket-wrapped (top down)

You have swept the chimney haven’t you? This is a MUST. Otherwise the loose soot is still a fire hazard and the person helping fit a chimney liner from inside the property will be covered in soot. The room may also fill with billowing soot dust.

Sweeping from bottom to top also tells you which pot belongs to your fireplace, something you obviously need to know. Shortly you will be dropping a weight attached to a rope down the chimney; you do not want this knocking loads of soot off the walls of the flue and into the fireplace of another room (likely with a beige carpet!).

One stove fitter I heard about swept a chimney from the top down. Trouble was he got the wrong pot and the customer’s lounge was filled with a layer of soot. Full re-decoration and all new soft furnishings was the result (and a new TV).

Image below: What happens when the cherrypicker fails to arrive (note that I did use a climbing rope/harness etc).

Preparing your chimney liner

Before we go any further let’s do a quick overview of what is going to happen. You are going to drag a 10 metre (or whatever) stainless steel tube to the top of your chimney stack. You are going to drop a rope down the chimney (with a weight on the end) so your helper can grab it from within the fireplace (other end secured to one end of liner). You are going to use both hands to feed that liner down the chimney whilst your helper pulls down on the rope. If you are lucky the liner slips through the chimney eith ease.

The liner might get stuck on a bend. Then you have to pull it back up a bit, then push it down a bit and even maybe spin the whole lot 180 degrees (remember you might have X metres of the liner being dragged around your roof at this stage). Likely you’ll have a TV aerial trying to take your eye out whilst the liner plays rough with one of your nipples.

Image: A £60,000 cherry picker. Approx. £200 to hire for one day with subsequent days £100 (2009 prices). This particular roof was a little steep for us!

TIME TO STEP BACK AND THINK OF SAFETY. CAN YOU ARRANGE FOR SCAFFOLDING? WILL A CHERRY FITTER REACH? HOW ABOUT A PLATFORM?

It’s your call. I am happy in some circumstances to use ladders and cat ladders). However I always wear a professional harness and associated safety equipment.

The liner will likely arrive in a coil. Uncoil it. You may notice that it has arrows printed on it. These arrows should always point to the sky when the liner is fitted (they show the smoke direction). DO NOT fit the liner upside down. Some brands can be fitted either way including Silvacore and Duraflue at the time of writing (see the product page on this site to be sure).

Fit the end cone to the liner (you did order one didn’t you or one of our fitting packs has one in you lucky person?) using strong tape (gaffer tape) lots of it or self tapping screws. If the cone has no “tie off handle” then you need to drill a hole in it and slip a short length of rope through, tying a large knot inside the cone. See pic “Nose cone”.

Check!

Arrows pointing up to the sky if liner has arrows on it?

Your helper down in the fireplace area should now put on their mask, goggles and hard hat.

YOU SHOULD NOT BE PROCEEDING WITHOUT ENSURING THE FIREPLACE LINTEL IS IN PLACE AND SUITABLE.

Time to slide that liner down the chimney

Connect your long rope to the short rope connected to the cone. Connect a weight to the other end of that long rope. Take the weight to the top of the chimney and lower it down slowly until your helper has it.

Feed the liner down the chimney. Your helper is pulling and you are pushing. Hopefully the liner will slip easily down the chimney and within minutes your helper is shouting “yeeeeehaaaaaa!” as he spits soot from his mouth. The cone enters the fireplace (more likely a swift outcome with a large chimney or a 5″ liner). It is often good to have a third person running in and out of the house passing messages from you to your helper, somebody calm and smiling.

But, if the liner stops and will not feed further then stop and take a breather. When ready pull it back and try again, hopefully after a few attempts it will go.

If it will not go then you have to start thinking - why? If it is in the first few metres from the top then it will likely be getting stuck in the loft area (where chimney flues often split away from each other and run off to their various rooms).

Dealing with a stuck chimney liner

If the liner does get stuck here then you can try the following:

Try “turning the liner 90 degrees” whilst you and your helper attempt to pull push as before. This works if the liner has turned one bend and is not set up for the next bend (has bent itself to point the wrong way). Then try 180 degrees. Any “spinning” is a lot easier for a double bend lower down in the chimney than this high up though; due to the sheer amount of liner sticking out of the chimney and lying on the roof.

Most likely you will have to break into the chimney from the inside or outside of the house and help the liner on its way. If stuck in the loft then this can be easy due to “making a mess in the attic who cares syndrome”. It will be a differnt matter if the attic is a loft conversion with the liner stuck behind little Charlotte’s Princess Pony wallpaper.

Another option is to withdraw the liner and try pulling it up from the bottom to the top (some bends are easier one way than the other). I suggest that this is only a remote possibility and do not really recommend this option except as a last resort. If you do try this remember that any ARROWS MUST POINT SKYWARDS.

You are warming towards the DEFRA approved stove with the 5″ liner now I guess…? As a guide, out of all the 6″ liners I have fitted I would say 60% give no problem, 25% are a fight but we get there without breaking through walls, 10% we break through the wall somewhere and 5% we give up. With 5″ liners: we have never had a problem fitting a 5″ liner (say 10% a bit of a grunt).

Note that it may not be possible to break into the chimney in some stone or rubble built properties. Luckily these usually have large diameter chimneys (we get a lot of these in North Wales).

If you cannot get the liner down the chimney and cannot break through the wall? You may need to put the liner on Ebay and look at having the chimney concrete lined.

Anyway, enough of the doom and gloom. Hopefully you arrive at the stage where you have a little liner sticking out the fireplace and a little sticking out the chimney stack or pot.

What you do next depends on whether you are pouring Vermiculite around the liner or not pouring Vermiculite around the liner. Scroll down to “Time to look at your chimney pot”.

Image below: Stuck liner. Within this loft there are four flues. The places where the liner gets stuck are obvious as in this case – you can see the holes we made to assist the liner around the bends. The liner is quite flexible but some bends cause trouble – especially for 6″ or wider diameter liners.

Sliding in a blanket-wrapped liner (bottom up)

You will most likely be blanket wrapping your liner if you have a huge chimney (Inglenook style maybe). Only try this if you know your chimney is of a suitable diameter.

I recommend blanket-style wrap as it is easy to fit and lighter than some others. It is supplied ready to go with the proper connectors.

I tried Rockwool once and never again. I itched and scratched like a farmer’s dog and it was extremely heavy.

Fitting is straightforward. Instead of feeding it down the chimney you haul it up the chimney. The person at the top has to have a very secure platform (e.g. scaffolding). A cherry picker might work but add the liner and Chimwrap weight to the maximum allowed by the cherry picker. I managed this once on a very sturdy stack that I could sit atop of and strap myself to. For connection at the top refer to the “inside chimney pot method” (basically you are hanging a lot of weight so will be best mortaring the liner into the pot). Ps. I hated doing blanket wrap jobs as it was sooo heavy. Do not even think about it if your chimney is less than 18" across as not worth the hassle.

Time to look at your chimney pot

Your liner needs to be connected at the chimney pot. There are two standard methods of achieving this:

1. Hanging cowl method (no insulation).

2. Inside chimney pot method (with Vermiculite or blanket wrap).

A third method can be used when you wish to add Vermiculite but wish to use your existing pot.

3. Vermiculite via existing pot.

Hanging cowl method (no insulation)

This is a very simple method with many advantages and some disadvantages. Essentially you hang your liner from the cowl, the cowl having a male tube that inserts into the female liner with a Jubilee clip clamping the female liner around the male tube.

The cowl comes with two Jubilee clips. One clip wraps around the three inner straps to connect the liner to the cowl. The other clip attaches the outer three straps to the pot.

As can be seen the liner is now “hanging” from the cowl. I fit these very often as they are swift and effective. In practice the liner is usually well-supported by the tightness and various bends in the chimney flue (unless in a larger chimney and in this case the “within pot” is generally considered the better option especially if the liner has heavy insulation).

The hanging cowl has three key advantages:

1. Fast to fit

2. If your existing pot is suitable you do not need to fit a new pot.

3. The liner can be slid up or down the chimney a little at any stage in the stove fitting process to aid fitting the stove.

The hanging cowl has two key disadvantages:

1. If you wish to add Vermiculite to your chimney you cannot add the jubilee clip that holds the liner to the snout. In this case the Vermiculite will hold the liner solid anyway so just ignore that clip.So really this is not a disadvantage just an observation.

2. If your liner is insulated with Chimwrap or Rockwall it will be very heavy. It is better in this instance to mortar it into the pot for full strength.

Note: As long as your liner will fit down the pot then many pots will be okay for the hanging cowl – it all comes down to aesthetics. Our hanging cowl will have the permitted chimney pot diameter on the cowl product page. However, anything that it is very tall or with an ornamental top can be cropped to make life easier when fitting or improve the aesthetics. But first check out Bishop Cowl on the website as this is designed for tall, ornamental pots. I often crop pots.

To cut a pot down you need an angle grinder with a suitable 115mm cutting disc (I use general purpose diamond tipped blades).

Warning

Chimney pots are very heavy and the part you cut off can be very heavy. The weight of the top part, when it comes away from the bottom part, can trap your cutting blade causing your angle grinder to to spasm and jump. This is not a nice operation when at serious height. Also pots can break. Only attempt this if you are using a cherry-picker or have a suitable platform or scaffolding or a suitable base on which to work. NEVER attempt this from a ladder.

Image: One could probably fit a hanging cowl to any of the pots shown here. One could also cut off the tops of many of them.

Fit a liner: Inside chimney pot method (with Vermiculite or blanket wrap)

Top Plate And Top Clamp: The top plate and top clamp are used together as one a method of fixing the chimney liner at the top of the stack. It is necessary to remove the chimney pot, fit the chimney liner in place with the plate and clamp, and then refit the chimney pot once installed. The chimney liner passes through the hole in the plate and is gripped in place above this with the top clamp. For a secure fixing, it’s recommended to use a top sleeve. The top sleeve fits inside the top of the chimney liner and gives a solid inner for the top clamp to grip against. Fill the gap between the liner and the pot with a sand/cement mix.

Secure the pot by flaunching with one course of bricks (ideally if there is room) and a 3:1 sand cement mix.

Add a cowl that will prevent bird and rain egress. Cowls (must be for solid fuel as some are for gas and oil).

Note: If adding Vermiculite follow the instructions as detailed below but adapt as required: obviously you will pour the Vermiculite in before the plate goes on.

Vermiculite via an existing pot

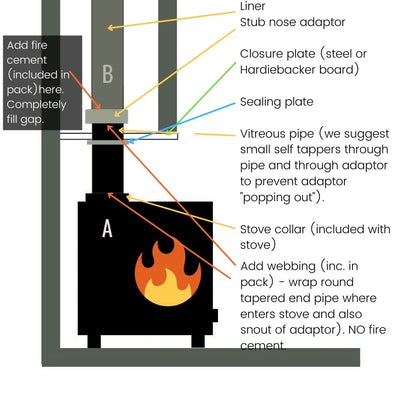

Firstly, you will not add your Vermiculite until the stove is fitted and the closure plate above the stove is fitted (otherwise it will just pour out of the chimney and into the room!). So you need to check out the stove fit section and come back here afterwards. Best to read it now to get an idea of what is to come later.

You will be in the position as seen in the picture and will pour around the liner (unless pouring Vermiculite PRIOR to the pot going on and then you will find it even easier – just fill that chimney up).

Vermiculite (Micafil, pictured, is a brand name) is supplied in bags. It resembles a muesli breakfast cereal. It is very light and will be taken by the wind easily.

Vermiculite cannot catch fire and is used to insulate around chimney liners. It is poured into the top of the chimney and will cascade down the chimney onto the closure plate, filling the gap between the liner and the chimney itself all the way to the top.

Vermiculite is only suitable for chimneys with a few inches of air gap. If your liner has more than a few inches of air gap you are going to use a heck of a lot of Vermiculite. To be safe allow 1 bag for each metre of chimney you need to fill. If you really hate the idea of having any left over you can budget for 0.8 bags per metre and hope you do not run short.

The simplest method of filling is to obtain one of those “Gorilla buckets” as favoured by builder’s or horsey folks. Cut a hole in the bottom just slightly smaller than the hole at the top of your pot then slip it over the bit of liner sticking out of your chimney pot. Tape it to the pot using Gaffer tape or similar. Passers by love to shout comments at this stage but just ignore them. If the protrusion of liner is “inside the bucket” then stuff a rag in the end to stop Vermiculite going down the liner.

Pour Vermiculite into your new “funnel” (the bucket”) and keep doing so until your chimney is full.

You want to end up with a picture that looks like so:

Note that this method of attaching liner to pot is not to be used if your liner is wrapped (rather than Vermiculite).

You will need to cut the liner just above the top of the pot (1-2cm) using an angle-grinder, hacksaw or tin snips. I like this 1 cm as it allows the sand cement mix to overlap onto the top of the pot, this all asisting its grip on the pot itself.

The Vermiculite will provide a base for the mix (you will of course have to extract some Vermiculite (wriggling the liner will “settle” the mix and this also works).

A 3:1 sand cement mix will do here.

You can now fit a standard cowl to your chimney pot (rainproof and birdproof).

Are you off to fit a chimney liner now?

FAQs

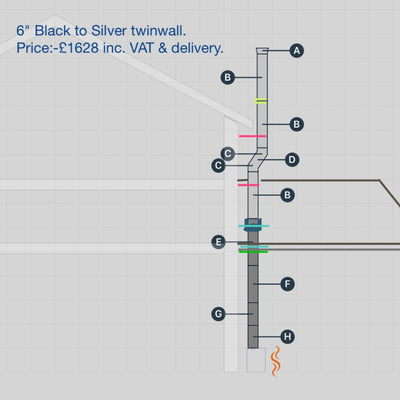

See all FAQsCosts correct as of April 2023:

Approx. costs if you have a chimney and fireplace ready to use: £750-£1,000 (save £500 by self-installing).

Approx. costs if you have a chimney but need the fireplace "opening up": £1,600-£2,200 (save £1200 by self-installing).

Approx. costs if you do not have a chimney and need a clip-together flue: Shed £475-£700. Bungalow £1500. 2-storey house £2500. Save £1,000-£1400 by self-installing.

Above figures include labour and materials but no appliance.

We, of course, advise you to purchase your stove and materials from Stovefitter's to ensure quality goods are installed (some installers use budget materials to increase margin). If you buy your stove from us (rather than your local small shop or installer) we have a lot more power when approaching manufacturer's with a warranty issue. Why is that? Because we buy many hundreds of stoves a year from these brands.

We do not fit stoves.

But we know a few who do!

Google: Hetas installers

Hetas are the trade body of registered UK installers.

Most installations will require that you slide a chimney liner down your chimney (flexible metal tube 5" or 6" in diameter). Do you have a narrow chimney and want to lessen the risk that a liner might not go down your chimney? Then make sure your chosen stove can use a 5" liner.

Must I line my chimney? Best read this article but most likely the answer is yes. Do I have to fit a chimney liner?

DEFRA-Exempt wood burning stoves with a 5″ collar can usually be fitted to a five inch liner rather than the usual 6″ minimum, making the installer's job much less stressful.

ALL OF THE 5KW STOVES WE SELL CAN BE FITTED TO A 5" CHIMNEY LINER.

I seriously suggest any self installer fits a 5" liner unless they know their chimney is large enough for a 6"!

What is the best chimney liner? Silvacore 904 (we sell it so of course we will say that ;-). What is the best chimney liner?

Useful links

Will your stove require an air vent within the room (some stone walls are very difficult to drill)?

5kW or under and wood burning stoves often do not require an air vent (new builds always require an air vent).

Useful links

What is the maximum output in kW of your "5kW" wood burning stove? The majority of manufacturers just specify the “nominal output” and this figure means very little in real life. The nominal is a figure the manufacturer chooses to sell the stove at - the stove is capable of reaching at least this output with one fuel load. Nominal means "capable of". But it is not the maximum.

Check out the size of the area where the logs will go (firebox size) as this varies enormously. The kW output is completely dependant on the amount of logs burning at any one time - more logs burning equals more heat. If you can fit three logs in stove A and just two logs in stove B then stove A will be capable of throwing out 33% more heat.

DO NOT TRUST MANUFACTURERS’ kW RATINGS as manufacturers specify what output they desire to sell the stove at and testing allows for much “playing with the figures”. This is why you can get very small 5kW stoves (e.g. Aga Little Wenlock) and very large 5kW stoves (e.g. DG Ivar 5 by Dik Geurts which is actually rated 5kW but has a MUCH larger firebox than the Ekol Crystal 5 by Ekol Stoves). A Crystal 5k might get to 5kW and not be capable of any higher whilst a DG Ivar, despite being rated at 5kW, can get to 8kW with a full fuel load.

Note that, over time, one might damage the internal firebricks of a stove by running at a higher load than the manufacturer's suggest. Firebricks are easily replaceable.

Useful links

Will your wood burning stove fit in your recess WITH the required air gaps around it? This is obviously not an issue if your stove will be freestanding.

Air gaps to non-combustible materials (brick, stone etc.) are usually "as close as you like" legally but manufacturers will sometimes specify a recommendation. This recommendation is there to allow heat to escape from the recess into the room - so you get the heat benefit rather than the heat soaking into the building structure and being lost. If no gap to non-combustibles recommended then we suggest 50-100mm air gap left and right of stove, 50mm behind and 100mm above.

Are you in a Smoke Control Area (usually built up areas)?

Choose your stove accordingly.

A stove must be DEFRA-Approved if you wish to burn wood in a smoke control area.

ALL OF THE STOVES WE SELL ARE DEFRA APPROVED FOR SMOKE CONTROL AREAS.

In simple terms if a stove has an efficiency rating of 70% then 30% of the heat from your logs goes up the chimney.

If a stove has an efficiency rating of 90% then only 10% goes up the chimney.

So think of this in terms of how many logs you have to chop/buy.

Example: A Saltfire Peanut 5 by Saltfire Stoves in Dorset has an efficiciency of 80%.

A tall chimney (6m or more) that is lined will be happy with an efficient stove.

Efficiency importance can be said to be overrated and anything between 75% and 85% is fine. Go much higher and performance can actually suffer (smoke in room when opening door to reload, blackening of glass).

Many modern stoves can go on 12mm thick hearths. Others require full, 5″ thick constructional hearths. All of the stoves we sell state whether or not a 12mm hearth is suitable.More about hearths for wood stoves here.

Helpful links

Can you can talk to somebody on the phone should you need to after the wood burning stove has been delivered, especially if you are self installing? Will the staff at “wesellzillionsofstoves.com” be able to assist with any installation issues? What if there are any problems after install?

Do yourself a favour before ordering stoves or materials on the Internet: Go to Trustpilot and type in the company name before you buy. Some companies advertising at the top of search engines are not good news - check for yourself.

When striving to find thebest 5kW wood burning stovesyou will likely be bewildered by the choice. There are many to choose from. The question I get asked most in our shop is “why should I pay <£1,000> for this one when this other one is just <£500>?”. Here is the very simple answer:the cheaper wood stoves are made in Chinaor Eastern Europe whilst the more expensive are made in Western Europe (or sometimes the USA). Here are a few examples where a more expensive stove might excel over a cheaper stove:

- Aesthetics (more time spent on design)

- Hinges (sometimes hidden on more expensive stoves)

- Better quality glass

- Thicker steel (longer life)

- Improved door locking mechanisms

- Longer warranty

- Improved controllabilty of flame due to more resource invested on design of air flow within stove

- Brushed steel fittings instead of cheapy chrome look

Open and close the door on a cheap Chinese stove. Then open and close the door on a DG stove, Arada stoves, Woodford stoves, Hamlet stoves or Saltfire stoves. You’ll understand the difference.

Stove pricing reminds me of wine pricing. A £20 bottle of wine is not double the quality of a £10 bottle of wine (the drinking experience might be improved by 20% as an example). We are talking “the law of diminishing returns here. They are all “fire in a metal box” at the end of the day.

Yes. However, there are specific regulations and restrictions in place to address air pollution concerns, particularly in areas designated as Smoke Control Areas. In these areas, only approved "smokeless" fuels or exempt appliances, such as Defra-approved wood-burning stoves, can be used. These stoves are designed to burn wood more efficiently and produce fewer emissions.

All the stoves we sell are DEFRA approved and Eco-design approved and suitable for all areas of the UK.

More buying guides

View All

How to choose a wood burning stove for your property (includes infographic)

Infographics

What size wood stove do I need? Don't let manufacturers fool you!

Buying Guides

Do I need an air vent for a wood burning stove? If I do not bother?

Buying & DIY

Knowledge Tree: Process of buying and installing a wood burning stove

Buying & DIY

Chinese wood burners – should I buy one or are they all crap?

Buying Guides

What else do I need to buy to install a wood burning stove?

DIY Guides

Infographics for wood burning stove purchase and install

Infographics

Wood burning or multifuel stove? A stove fitter decides.

Buying Guides

A few words from Julian

Buying & DIY